Important:

Important:

Principal rule:

Production drawings can only be created on the basis of an itemized and saved model drawing.

Important:

Important:

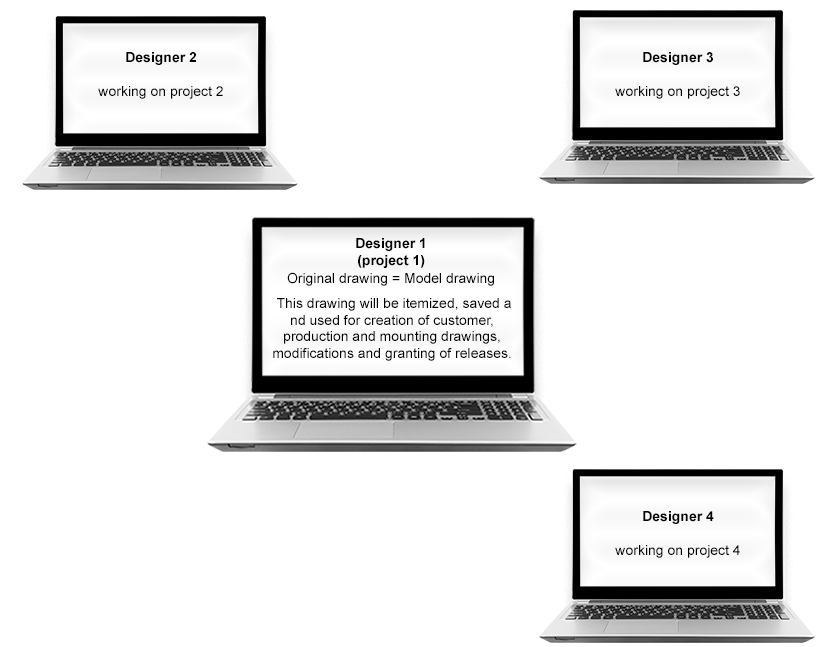

If the model drawing is a small one, the project can be handled within one model drawing. All assemblies and parts will be processed in one model drawing, they will be itemized and saved there. Customer drawings, production drawings and mounting drawings will be created, released ans saved based on this model drawing.

|

Unambiguous item numbers in the original drawing |

|

Derived drawing(s) can only be created after completion of all assemblies. |

|

|

If this method has been chosen, no other engineers can work simultaneously on the model drawing! |

Example 1: Creating Assemblies and Deriving Drawings in Original Model Drawing.

Example 1: Creating Assemblies and Deriving Drawings in Original Model Drawing.

If you are dealing with large and complex model drawings it often makes sense to split the large model drawing into several smaller ones (Concurrent Engineering). This improves efficiency and allows a working of several engineers on one project.

For this purpose, the original model drawing will be subdivided into suitable structure assemblies and saved in a non-itemized state. To define an assembly as a structure assembly, use the Part attributes function ion the context menu of the assembly. In the dialogue window, choose Part type: Structure assembly. Structure assemblies will be marked with the  symbol in the part structure of the ICN. Further information on structure assemblies can be found in the What are Structure Assemblies? topic.

symbol in the part structure of the ICN. Further information on structure assemblies can be found in the What are Structure Assemblies? topic.

The structure assemblies of the model drawing are saved separately as externally referenced detail drawings.

Next, one can choose between the following two procedures:

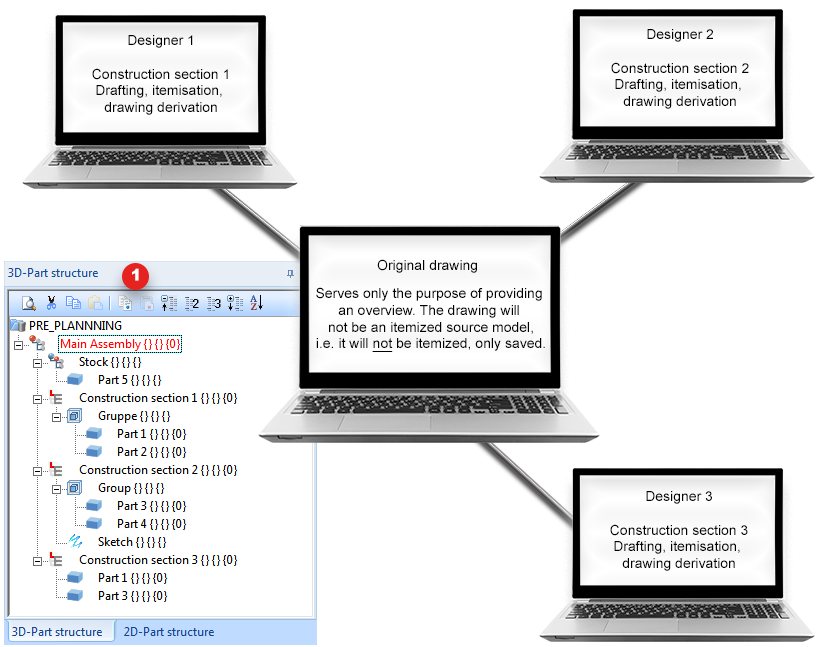

The original drawing is split into suitable structure assemblies and saved in a non-itemized state. To be on the safe side, the itemisation in the original drawing can also be prevented by deactivating the Itemisation checkbox in the document master of the original drawing (document attribute ITEMISATIONMODEL). As a result, the original model drawing will not be an itemized source model.

The structure assemblies of the model drawing are saved individually as externally referenced detail drawings. These referenced detail drawings can then be edited and itemized on different workstations. Customer drawings, production drawings and mounting drawings are created, released and modified in the detail drawing. Changes to the detail drawings are, of course, also transferred to the original model drawing due to referencing. In the process, the original model drawing serves only the purpose of providing an overview.

(1) shows the structure in the HiCAD ICN with structure assemblies. These are externally referenced, namely, as detail drawings.

If this method has been chosen, the model drawings called Construction section 1, Construction section 2 and Construction section 3 will be itemized independently from each other (identical part search takes place per Construction section). Therefore, the responsible engineers should inform each other about the start values they intend to use in the itemisation settings. Otherwise it might happen that non-identical parts will have identical item numbers (e.g. 100) when taking a look at the drawings for the whole project later.

This can be avoided by reserving a specific range of item number for each of the individual model drawings (Construction sections 1 - 3).

|

The editing of the assemblies can take place at the same time at different workstations. After completing an assembly the corresponding drawings can be derived immediately. |

|

In the original drawing, identical parts may have different item numbers. |

This method is described in detail in Example 2a.

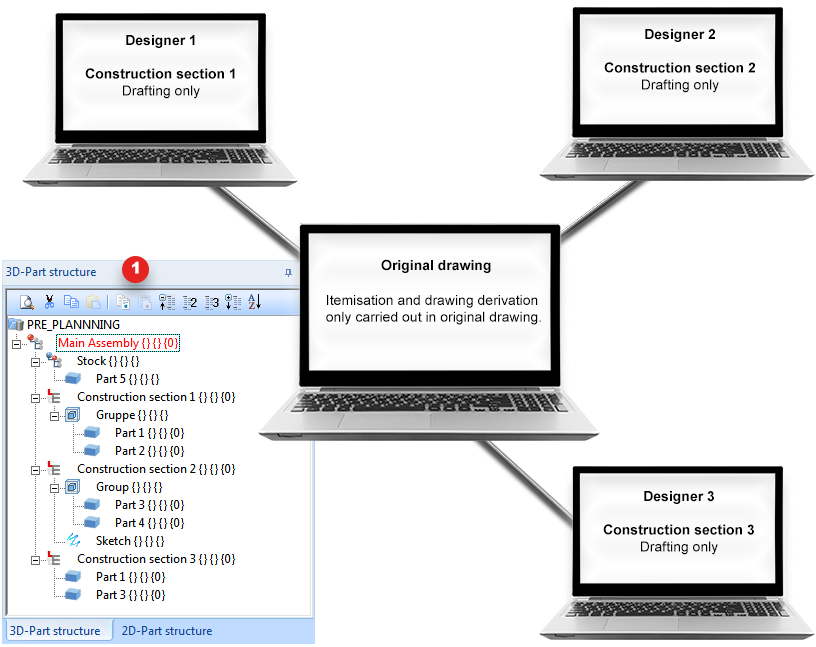

The original model drawing is split into suitable structure assemblies and saved in a non-itemized state. The structure assemblies are saved individually as externally referenced detail drawings. These externally referenced detail drawings can then be edited and saved - but not itemized - on different workstations. After completion of all structure assemblies the original model drawing will be updated. Itemisation of all structure assemblies and drawing derivations will then take place in the original model drawing; that is, the original model drawing serves as the itemized source model here.

To be on the safe side, the itemisation in the detail drawings can also be prevented by deactivating the Itemisation checkbox in the document masters of the detail drawings (document attribute ITEMISATIONMODEL). As a result, the detail drawings will be no itemized source models.

(1) shows the structure in the HiCAD ICN with structure assemblies. These are externally referenced, namely, as detail drawings.

If this method has been chosen, the model drawings called Construction section 1, Construction section 2 and Construction section 3 will only be saved, but not itemized. Itemization will only take place in the original model drawing.

However, please note that productions drawings etc. can only be derived in the original model drawing.

|

|

The editing of the assemblies can be distributed among different workstations. |

|

|

The item numbers in the original model drawing are unambiguous. |

|

|

Drawing derivation in the original model drawing can only take place after completion of all assemblies. |

This method is described in detail in Example 2b.

Requirements for a Smooth Operation (ManBIM) • Important Information (ManBIM) • Overview of Functions (ManBIM) • Examples (ManBIM)

|

© Copyright 1994-2018, ISD Software und Systeme GmbH |