Pipe Parts: Flanges

|

When you insert flanges, please note that Connection 1 always refers to the flange connection side while Connection 2 refers to the pipe connection side. |

|

When working with user-defined variants for flanges or parts with flanges, please read the Notes on bolted flange connections in the Creating New Parts and Variants topic!

Flange

Plant Engineering > New > Pipe parts > Flange

When you insert a flange, you have the following insertion options.

|

|

|

|

|

|

|

|

Connect flange

When you select the Connect option, (additional) search criteria from the properties of the target part and its selected connection are used (Attributes: NENNWEITE (nominal diameter) and ANSCHLUSSART (connection type). Let us assume that the standard designation of an accessory is contained in the ANSCHLUSSART attribute and it this accessory is a flange, it is added to the search criteria in the NORMBEZEICHNUNG (standard designation) attribute. The insertion direction of the flange depends on the type of target connection, i.e.

If the target object is a flange, and the target connection is on the flange surface, HiCAD inserts an identical flange. HiCAD now displays the crosshairs, thus enabling you to select a new target point for the fitting of the next flange. Search criteria is enhanced by data extracted from the NORMBEZEICHNUNG of the previously inserted flange.

|

|

|

Connect 2 flanges

Select a part with the crosshairs. HiCAD inserts suitable flanges in the appropriate direction in all connections on the part, provided that the connection is located on a guideline and has not yet been joined to the connection of another part. In this case, the same search criteria as those for individual flange insertion apply. |

|

|

Connect all

HiCAD inserts suitable flanges in the vacant flange connections on all guidelines of the active pipeline, provided that the respective connections are located within a guideline, and are not orientated outwards at the end of a guideline, If a guideline end point is located on a flange connection of a part that does not belong to the active pipeline, HiCAD inserts a suitable flange anyway. In this case, the same search criteria as those for individual flange insertion apply. |

|

|

On guideline ends

|

When connecting one or several flanges, the search criteria for the flange to be fitted always refer to the flange connection to which the flange is to be attached. This means that the nominal diameter assigned to the pipeline or the guideline is always ignored, i.e. even if the Ignore nominal diameter option has not been activated. If the flange connection to which the part is to be fitted belongs to a flange, the same flange is inserted as a counter-flange; this applies even if a pipe class not containing this flange has been assigned to the pipeline.

When connecting one or several flanges, the search criteria for the flange to be fitted always refer to the flange connection to which the flange is to be attached. This means that the nominal diameter assigned to the pipeline or the guideline is always ignored, i.e. even if the Ignore nominal diameter option has not been activated. If the flange connection to which the part is to be fitted belongs to a flange, the same flange is inserted as a counter-flange; this applies even if a pipe class not containing this flange has been assigned to the pipeline.

Blank flange

Plant Engineering > New > Pipe parts > Blank flange

This function is only available when guideline mode is active, and can be handled almost in the same way as the Connect flange function. Provided that the attribute exists for the target object, DRUCK (pressure) attribute settings are added to search criteria.

A blank flange can also be attached to a flange which is located on the end of a guideline. In this case the blank flange will not be placed on a guideline. The search criteria for the blank flange to be fitted always refer to the flange connection to which the flange is to be attached. This means that the nominal diameter assigned to the pipeline or the guideline is always ignored, i.e. even if the Ignore nominal diameter option has not been activated.

Loose flange

The following parts are available as "loose flanges" in HiCAD:

- EN 1092-1/01: Plate flange for welding

- EN 1092-1/02/32 (EN 1092-1/02 with EN 1092-1/32): Loose plate flange with weld-on plate collar

- EN 1092-1/12: Slip-on flange for welding

Loose flanges can not only be placed through an automatism during automatic placing of parts on guidelines, but also be added to a pipeline manually.

Please note the following:

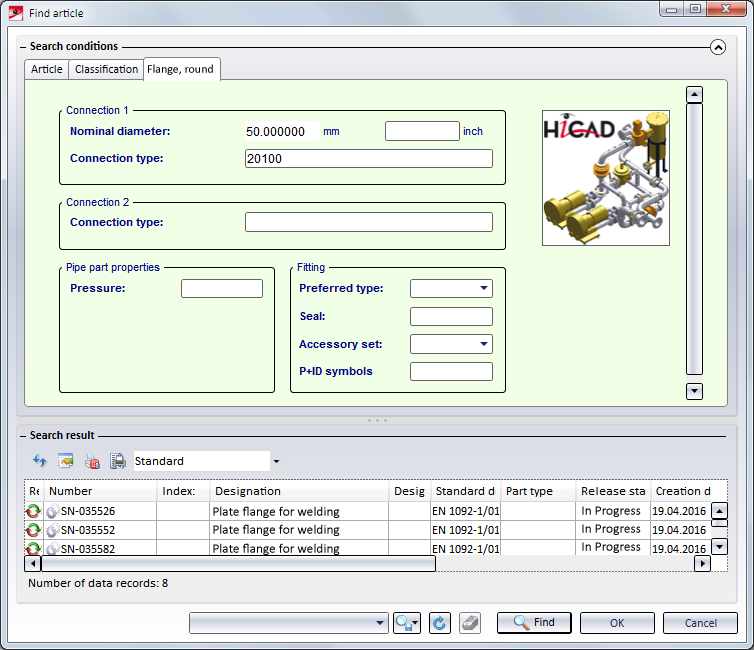

- The Connection type attribute of the HELiOS article search mask is now editable. The default valie of the search field er Default-Wert für das Suchfeld Connection type is 20000 and originated from the file sml_flansch.xml in a standard installation. As loose flanges have the Connection type 20100, they will only be found if the search criteria will be adjusted accordingly.

- The manual insertion will only work if the guideline mode has been deactivated in the Plant Engineering settings.

- As a loose flange can only be usefully connected at the end of a pipe part, you need to select, the Connection 1 to target connection option via the context menu (right-click) during insertion.

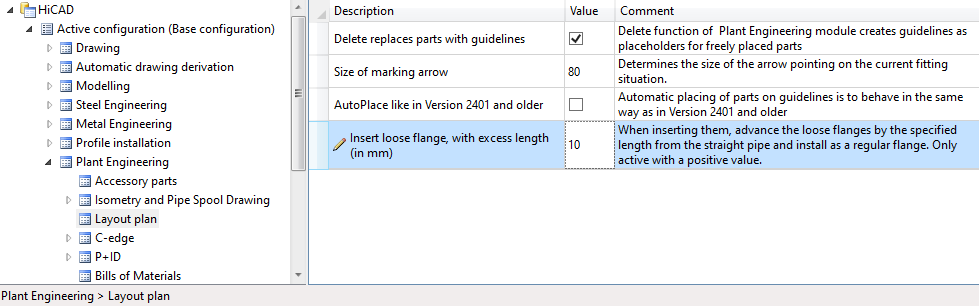

- Loose flanges can be inserted as regular flanges from SP1 onwards. The loose flange is pushed down from the straight pipe by a fixed excess length. This value can be set in the Configuration Editor at Plant Engineering > Layout plan > Insert loose flange with excess length.

If you enter a value of 0 or a negative value, loose flanges will be installed as usual. If a positive value is entered, then each loose flange is installed like a regular flange. In particular, when connecting to a straight pipe, it is not necessary to connect with the first point as usual for loose flanges, but with the second point.The default setting is 0.

Please note:

Please note:

- Loose flanges belong to the part type Flanges. The ANSCHLUSSART (=CONNECTION_TYPE) attribute, however, must have the value 20100 !

- A loose flange on a free pipe end can be deleted individually. A loose flange which is attached to another flange connection can only be deleted if the pipe to which the flange belongs is deleted.

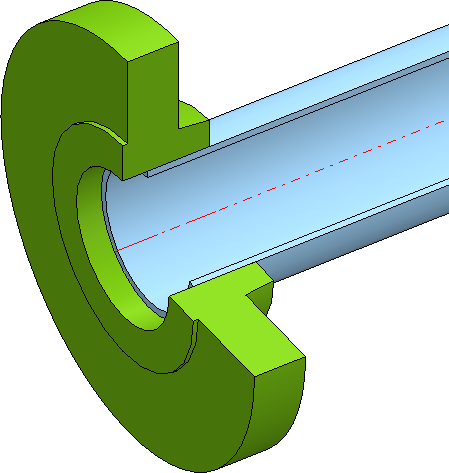

Welding neck with loose flanges

HiCAD supports the insertion of welding necks with loose flanges. In the standard part inventory for plant engineering, appropriate variants exist for this purpose.

In the form of the variants KM10357_WN_DIN.VAA and ROFI10357_WN_ISO.VAA, the standard part inventory contains two part families, which are classified as "real" flanges, but are in fact only welding necks.

In total, the following welding neck variants are available:

|

Variant |

Standard designation |

|

|---|---|---|

|

KM10357_WN_DIN.VAA |

Kieselmann 10357 |

|

|

ROFI10357_WN_ISO.VAA |

RO-FI 10357 |

Contains all sub-types of the modelled welding neck. |

|

ROFI10357_WN_ISO_R1.VAA |

RO-FI 10357 R1 |

Contain each one portion of the sub-types from ROFI10357_WN_ISO.VAA. |

|

ROFI10357_WN_ISO_R2.VAA |

RO-FI 10357 R2 |

|

The variants refer with their connection type to the (also new) loose flanges of the DIN 2642 standard, which are classified as fasteners:

|

Series |

Variant |

Standard designation |

|---|---|---|

|

1 |

N2642_LF_R1.VAA |

N2642 R1 |

|

2 |

N2642_LF_R2.VAA |

N2642 R2 |

The loose flanges of the series 1 match the variant ROFI10357_WN_ISO_R1.VAA. The loose flanges of the series 2 match the variants ROFI10357_WN_ISO_R2.VAA and KM10357_WN_DIN.VAA.

To model your own welding necks, you can choose between the following two options:

- Model flanging (=welding neck) as straight pipe

Here the flanging (i.e. the welding neck) is a straight pipe, to which regular loose flanges are assigned. This procedure is not optimal if you want to create an isometry of the pipeline, as the flange symbol of the loose flange will then be slightly displaced. - Model flanging (=welding neck) as flange

Here the flanging (=welding neck) has the part type "Flange", while the loose flange is an asymmetrical fastener. Since the flange symbol is assigned to the welding neck here, this will ensure that the position of the flange symbol in a generated isometry will not be affected by a possible moving of the loose flange.

Pipe Parts (PE) • Part Selection - Catalogue or Database (PE)