JACOB Pipe Systems - Using Push-In Pipes

As the straight JACOB pipes cannot be simply shortened because of their flanged edges, the utilization of push-in pipes is recommended for a fitting length adjustment. These pipes have a slightly reduced diameter at one of their ends, which allows their pushing into other pipe components, as you would do with a sleeve-nipple connection. At their other end, the pipes have a flange/flanged edge, enabling their regular insertion here.

JACOB push-in pipes

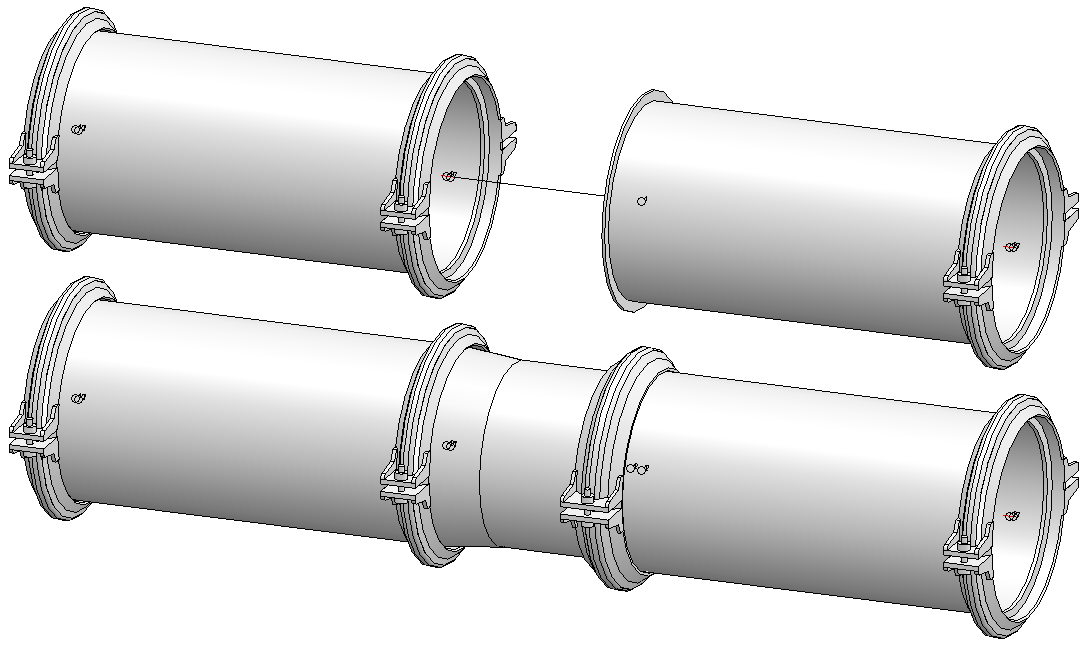

Through a variable connecting point along the centre axis the push-in pipe has, in contrast the normal straight JACOB pipes, an adjustable insertion length. This allows an automatic adjustment of the pipe length to close gaps in pipelines. To place push-in pipes on the corresponding, empty guideline sections, it is important that you keep to certain rules:

The push-in pie should generally be placed as the last component on the guideline. The empty section of the guideline must be shorter than the push-in pipe you want to use. If this is not the case, create further straight pipes until the push-in pipe is long enough to completely close the gap.

Pipeline before (top) and after (bottom) insertion of a push-in pipe

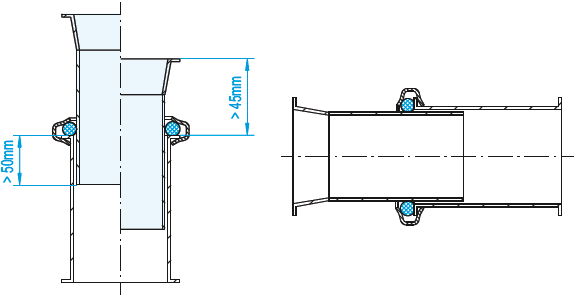

Since push-in pipes do not have the necessary flanges/flanged edges at their push- in ends, special fastening elements and seals are required at this connecting point. Accordingly, any seals and pull-rings must be removed before inserting the pipe.

Push-in pipes are produced with only one wall thickness for each nominal diameter. In case of a deviating wall thickness of the pipeline therefore is necessary to deactivate the Wall thickness (WANDDICKE) as a filter criterion on the Part search of the Plant Engineering Settings dialogue window.

If you want a shorter variant of an push-in pie, select Plant Engineering > Part Data Tools > Variant Editor  to create, in addition to the standard JACOB types, another sub-type with adjusted variable Lges.

to create, in addition to the standard JACOB types, another sub-type with adjusted variable Lges.

Please note:

As of HiCAD 2024, Jacob Push-in pipes get their Supplied length as a Length attribute. This is no longer adjusted by the dynamic route change. In the variant files of these push-in pipes, the attribute Arbitrarily divisible (BELIEBIG_TEILBAR) is set to 0=no. In addition, the attribute weight for Jacob Push-in pipes is taken directly from the database and is no longer interpreted as Weight per metre as with other straight pipes.