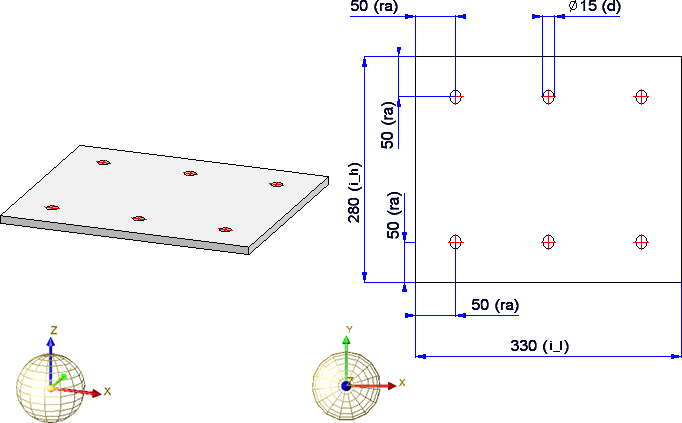

In the following example we will use a drilled Steel Engineering plate as installation element. The plate is to be derived from a sketch. Length and height of the plate are to be variable. The bores are to be arranged linear and equidistant (even) manner onto an axis. The number of bores is to be determined automatically on the basis of the maximum grid distance. The diameter of the bores, the distance of the bores to the plate edge and the maximum grid distance is to be variable.

- Step 1: Create the geometry of the installation element

- Step 2: Parameterize the installation element

- Step 3: Define a Fitting CS

- Step 4: Save the installation element to the catalogue

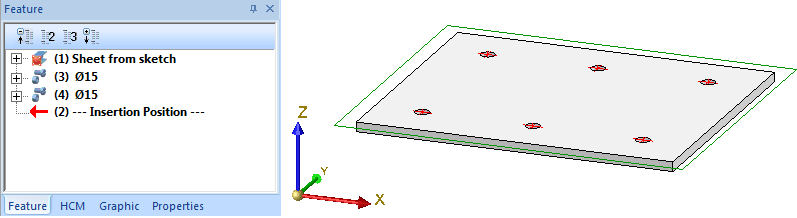

Step 1: Create the geometry of the installation element

The first step towards your own installation element is the definition of the part's geometry. Construct the part with the corresponding HiCAD functions.

Make sure that the Feature log is activated!

Make sure that the Feature log is activated!

Example:

- Create a new drawing file and switch to the Standard AXO view.

- Select Sketch > New

to create a new sketch.

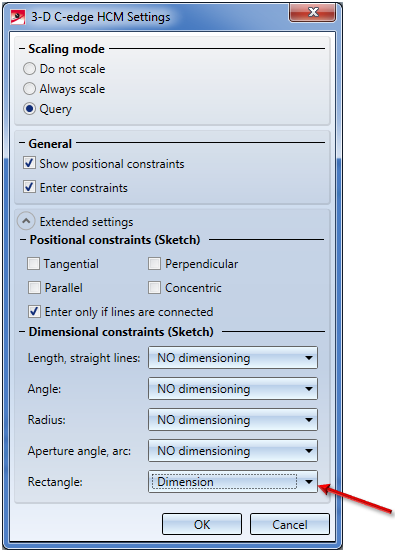

to create a new sketch. - Choose Sketch > HCM > Tools > Settings

. In the Extended settings, select the Rectangle: Dimension setting (these parametric dimensions are to be used later on).

. In the Extended settings, select the Rectangle: Dimension setting (these parametric dimensions are to be used later on).

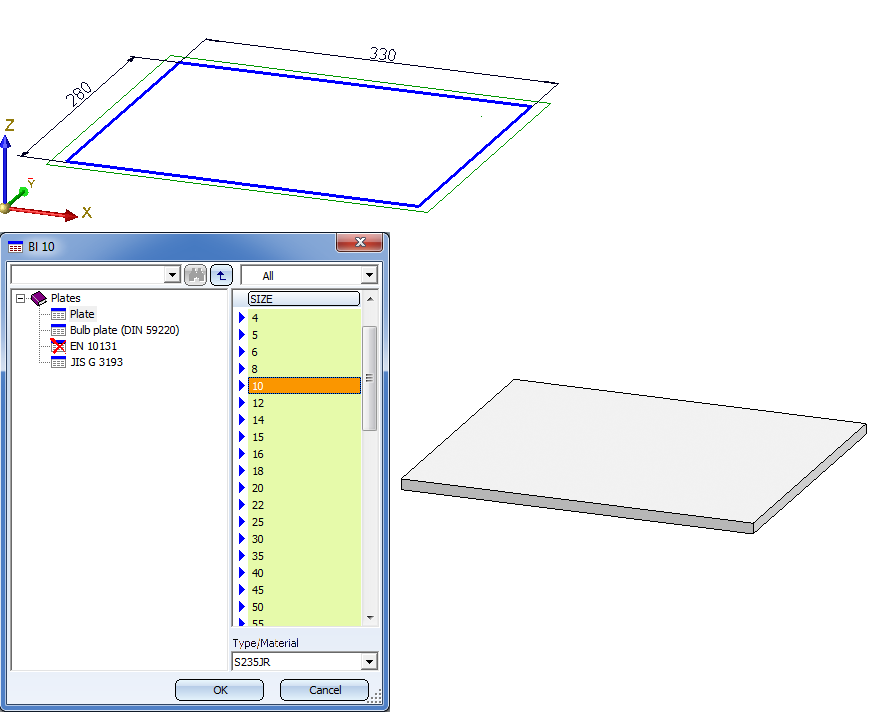

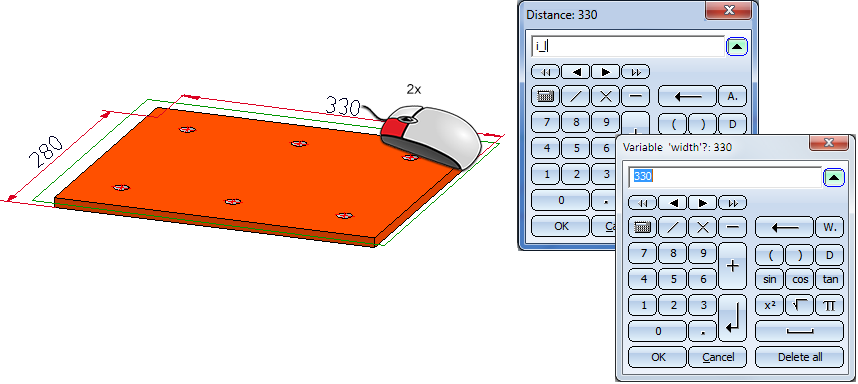

- Select Sketch > Draw > Rectangle

and draw a rectangle with the dimensions 330 x 280 (Length x Height).

and draw a rectangle with the dimensions 330 x 280 (Length x Height). - Switch to the Steel Engineering tab. Choose Plate, new > FromSkt

to derive a Steel Engineering plate from the sketch.

to derive a Steel Engineering plate from the sketch.

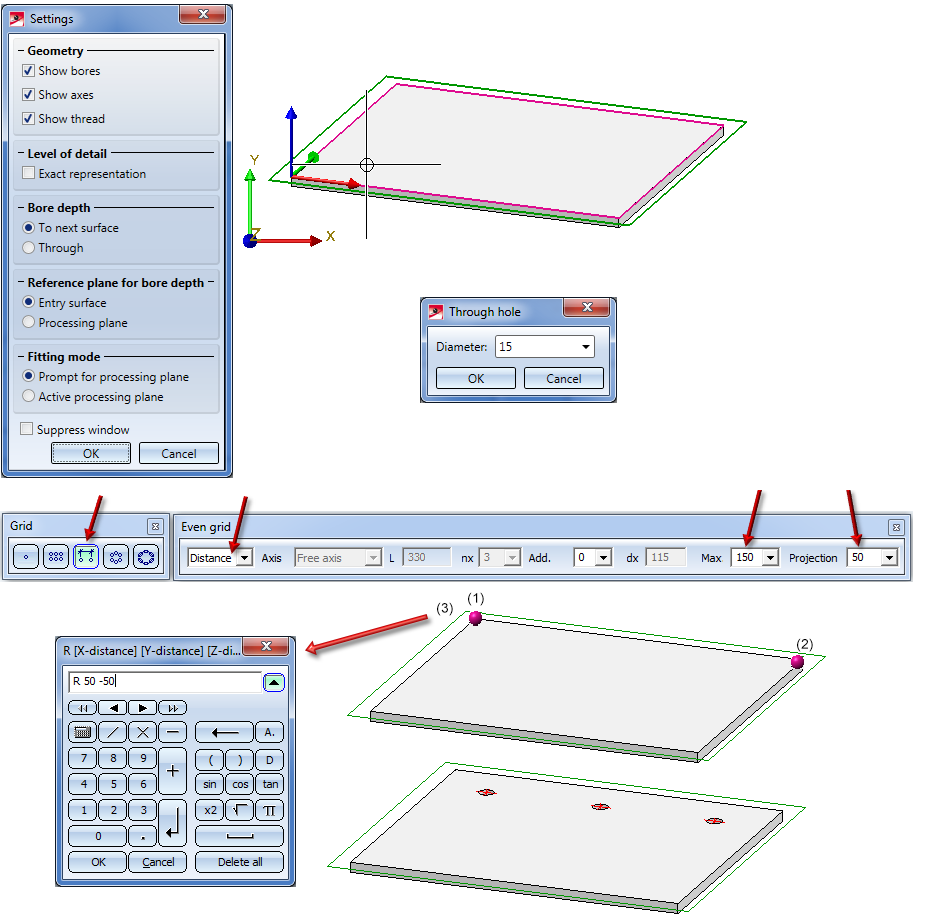

- Now create the upper row of bores: On the 3-D Standard tab, choose Standard Processings > Bore

.

. - Place the processing plane - as shown above - into the top surface of the plate.

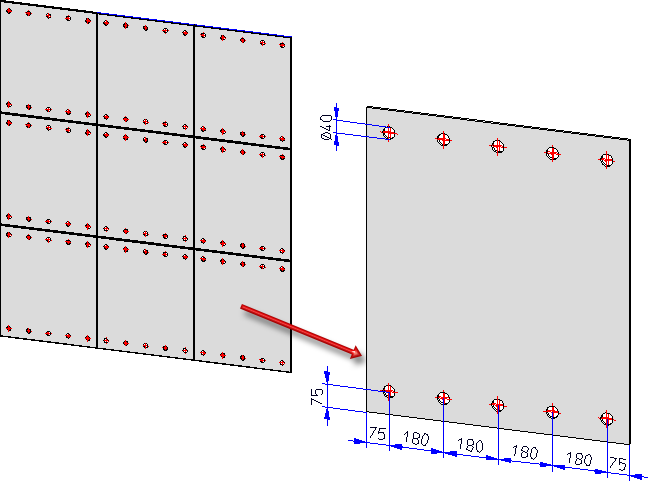

- The bores are to be directly inserted multiple times, with the individual bores to be arranged on one axis. In the Grid window, choose the Even grid option. We want to define a fixed maximum grid distance, i.e. the number of bores is to be automatically calculated on the basis of this distance. In the Even grid window choose the option Distance and enter the (Max)imum distance and the Projection (distance from edge).

- Then, determine the start point and the end point of the axis for the alignment of the bores. Choose the start point (1) and the end point (2) of the upper plate edge.

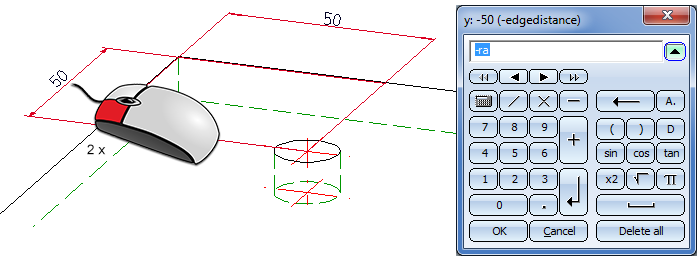

- Specify the insertion position by choosing the point option Relative R (via keyboard), then press ENTER, choose the start point (3) of the upper plate edge as reference point and enter the X- and Y-distance 50 -50.

- Proceed likewise to define the lower row of bores. Here, choose the lower plate edge as the axis for the even grid; reference point is the left point of the edge (Distance: 50 50).

Step 2: Parameterize the installation element

To ensure that the installation element will be automatically adjusted to the utilized sketch it needs to be parameterized. This is done by assigning variables or formulas and - if required - by assigning of HCM constraints.

In any case, the variables

- i_l (Length) and

- i_h (Height)

for the length and the height of the installation element must be used!

You can assign these variables either

- by double-clicking the corresponding Feature log entry,

- via the Edit formula function in the Feature context menu,

- via the context menu for parametric dimensions, or

- with a double-click on a parametric dimension.

Some functions also allow a direct use of variables.

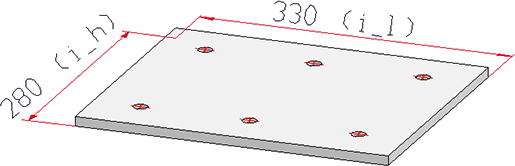

Please note that the parametric dimensions will only be displayed if the visibility settings for this type of dimensioning have been set accordingly. These can be specified via the Properties Parametric dimensions function in the context menu for parts. In this example you should select the If feature active option.

- Activate the feature Sheet from sketch. The plate will be highlighted and the parametric dimensions will be shown.

- Double-click on the dimension 330, enter the variable i_l and 330 as start value.

- Double-click on the dimension 280, enter the variable i_h and 280 as start value.

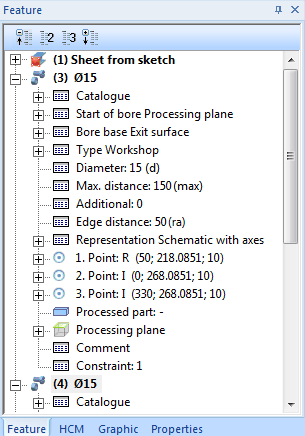

- Open the first feature (3) ∅ 15.

- Double-click the feature entry Diameter: 15-> Enter the variable d and the value 15.

- Double-click the feature entry Max. distance: 150 -> Enter the variable max and the value 150.

- Double-click the feature entry Edge distance: 50 -> Enter the variable ra and the value 50.

- The vertical distance to the upper edge of the plate is to be identical to the edge distance. To achieve this, double-click the corresponding parametric dimension in your drawing and enter the formula -ra (the negative input is required as we have selected the left point of the plate edge as the reference point for insertion and the bores are located beneath the edge, i.e. in negative Y-direction.

- Proceed likewise with the feature (4) ∅ 15. Here, no value inputs will be required, as the variables already have been assigned values. Here, too, you need to parameterize the vertical distance to the lower edge of the plate. In the drawing, double-click on the corresponding parametric dimension and enter ra (here positive, as the bores are located above the edge, i.e. in positive Y-direction.

Important:

Important:

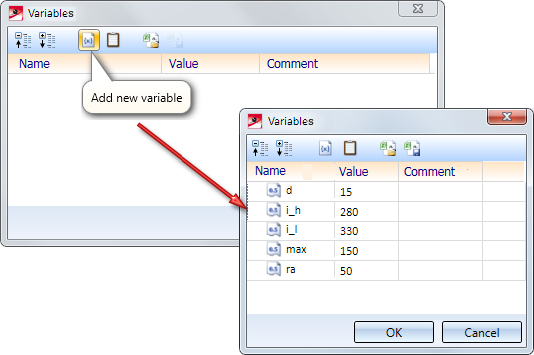

If the installation element is an assembly, all utilized variables must be assigned to this assembly!

Let us assume that the plate in this example belongs to an assembly, and this assembly is to be used as an installation element. In this case the parameters i_l, i_h, d, max and ra must be assigned to the assembly. To do this, right-click the name of the assembly in the ICN and choose Properties > Part variables. Then, select Add new variable in the Variables dialogue window and enter the name of the variable and its start value.

The plate can then be parameterized as described above.

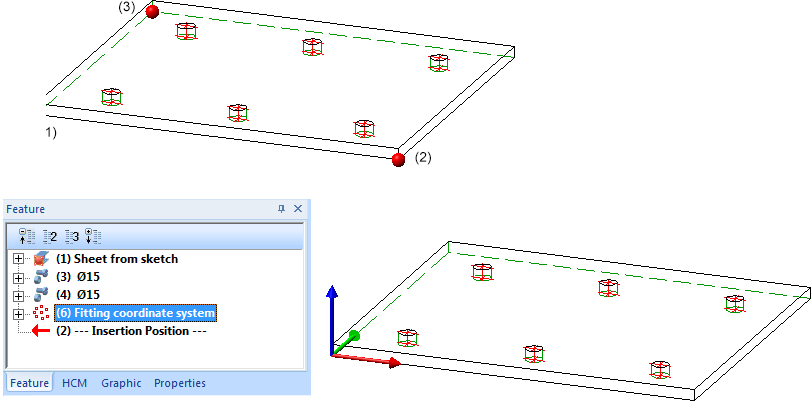

Step 3: Define the Fitting CS

The Fitting CS (FCS) determines the insertion direction of a part in space. It consists of 3 special points:

- the origin,

- one point on the X-axis, and

- one point in the (X-, Y-) half-plane.

If a 3-D part to which an Fitting CS has been assigned is loaded into a new model drawing, the points of the Fitting CS will be placed into the World CS. This defines the fitting direction in space.

The definition of a Fitting CS is particularly important if the installation element is an assembly. If this assembly is saved to the Element installation catalogue and no Fitting CS has been assigned to it, a Part CS of the assembly will be used as fitting coordinate system during its insertion. Please note that this can led to unwanted effects during the installation of the elements.

Please note:

Please note:

Not all assemblies have automatically a Feature log, e.g. assemblies that have been created with the Form assembly function, or, in case of the creation of new assemblies, with the New assembly function. If you assign a Fitting CS to these assemblies, no corresponding Feature entry will be created. To achieve its creation, you need to assign a so-called body creation feature to the assembly. To do this, right-click on the Feature window of the assembly and select the Switch feature on function in the context menu. After this, the definition of the Fitting CS will be entered as a Feature for these assembly types, too.

Continuation of the example:

As already mentioned, the sheet in this example is to be inserted in such a way that the bottom left corner lies in the bottom left corner of the selected sketch area. Therefore, a Fitting CS must be defined for the Sheet Metal main part

On the Drawing tab, choose Others > World CS  > Define Fitting CS

> Define Fitting CS  . Define the points as follows:

. Define the points as follows:

(1) New origin of the coordinate system

(2) Point on the X-axis

(3) Point on the Y-axis

The Fitting CS will then be entered in the Feature log.

The installation element is now completed and can be saved to the catalogue.

Step 4: Save the installation element to the catalogue

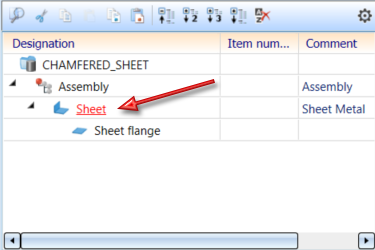

To save the installation element as a variant, choose Element installation > Save variant for element installation in the Civil Engineering functions docking window.

Please make sure that the Sheet Metal main part is active here.

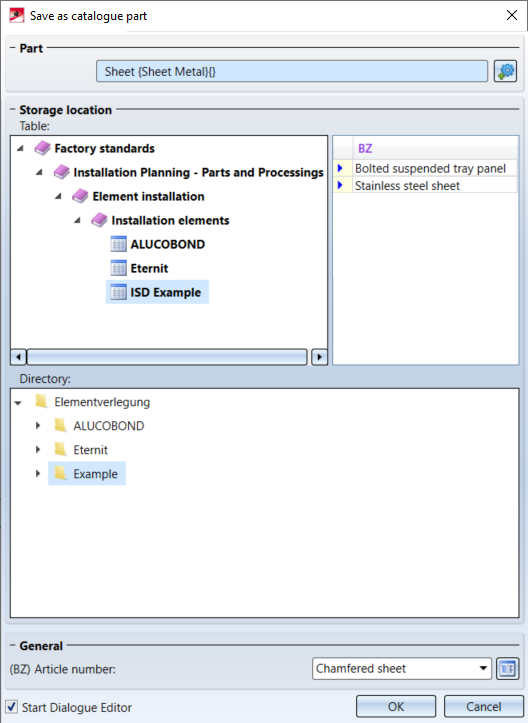

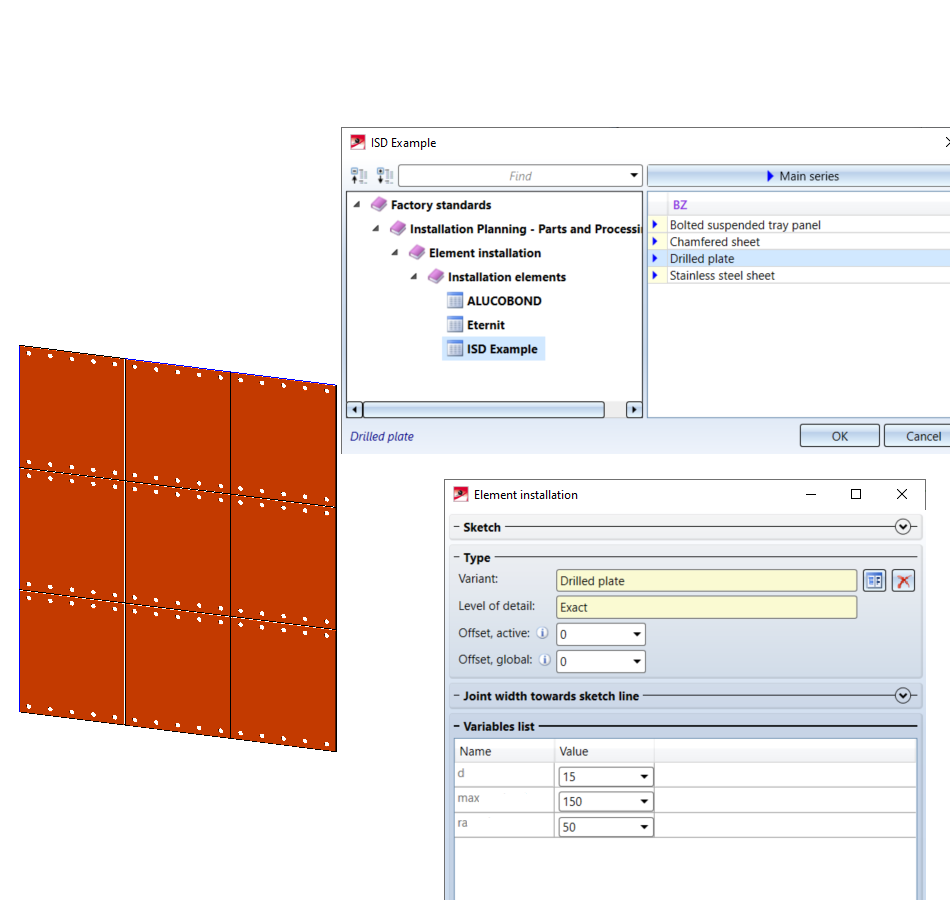

- Then, select the table in which the variant is to be stored, e.g. ISD Example.

- Select the directory in the HiCAD folder KATALOGE to which the part (as a KRA file) and the CSV file with the variables are to be saved, e.g. Example.

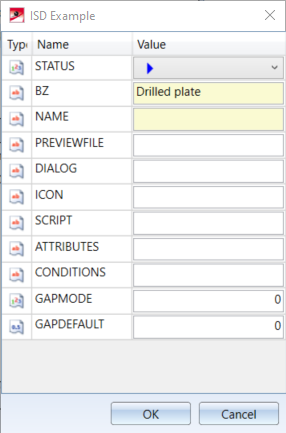

- If desired, change the name of the variant, e.g. to Drilled plate.

- Click the

symbol to define the contents of the table columns for the sheet metal (for example, to specify a preview image).

symbol to define the contents of the table columns for the sheet metal (for example, to specify a preview image).

- Since no user-defined dialogue is to be created here, deactivate the Start Dialogue Editor checkbox and exit the window with OK.

- The HiCAD folder KATALOGE now contains the files

- sheet.KRA and

- sheet.CSV.

at Werksnormen\Elementverlegung\Example.

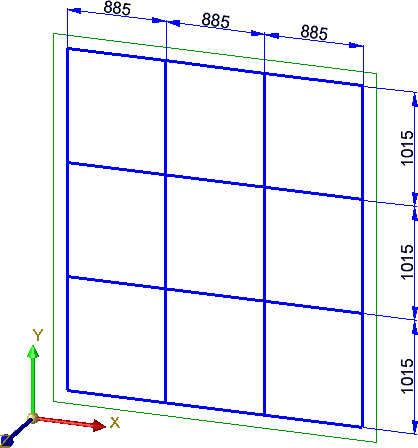

- The Chamfered sheet variant is now available in the ISD Example table and can be used for element installation, e.g. on the sketch shown below:

Result

Tip:

The dialogue shown in the example can also be designed individually. The HiCAD Dialogue Editor is available for this purpose. An example of an individual catalogue can be found here.