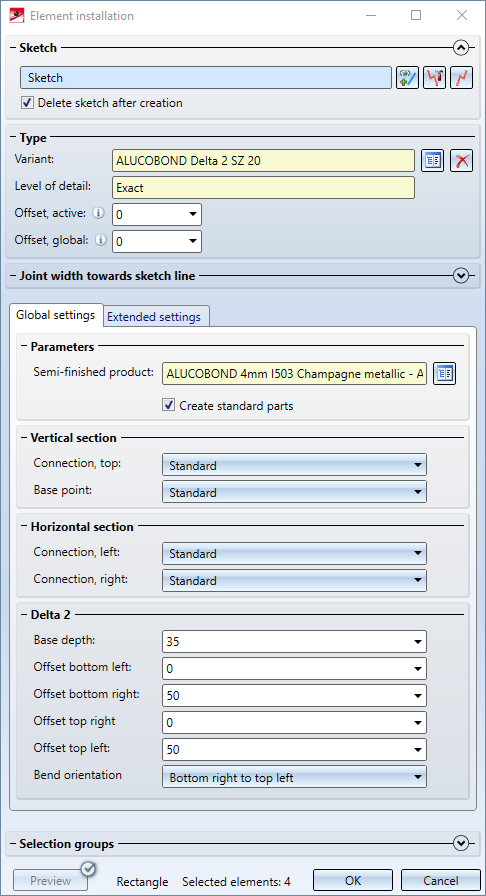

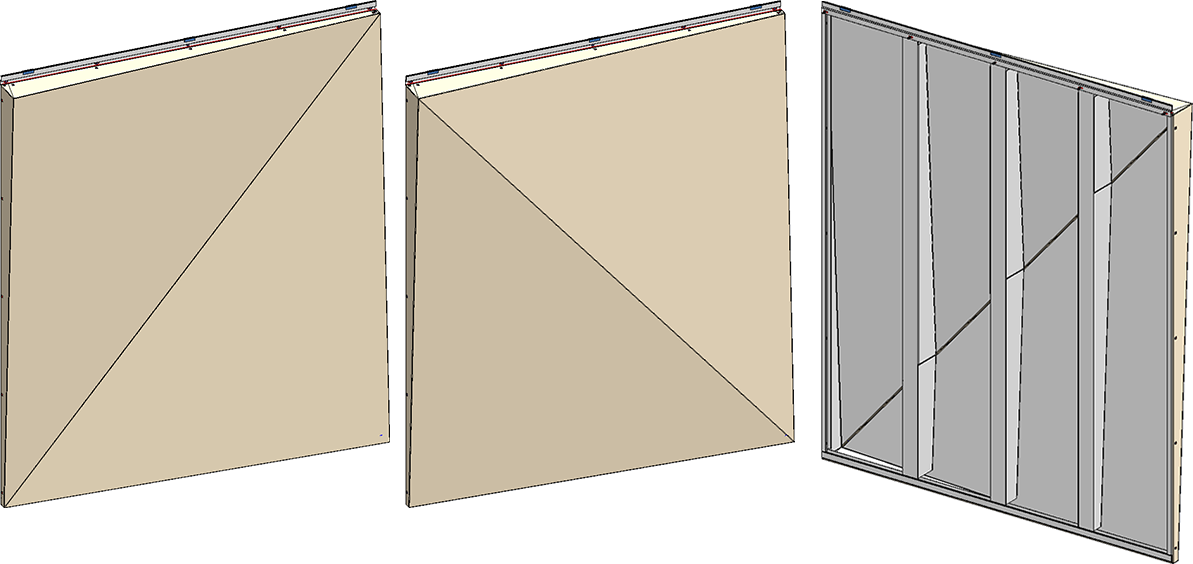

ALUCOBOND® SZ 20 (without accessories) panels can also be installed with a spatially folded base surface. For this the variant ALUCOBOND® - Delta 2 SZ 20 is available. Two tabs with setting options are available in the dialogue window:

Global settings

On this tab you select the desired semi-finished product as well as the parameters for the connection at the top, at the base point, left and right. Furthermore, you can select here whether standard parts (for fastening) are to be installed or not. The ISD default setting is that standard parts are created, i.e. the checkbox is active. If the checkbox is inactive, the standard parts are not listed in the BOM.

In the Delta 2 area you define the data of the folded surface.

The operation of the dialogue window is essentially the same as for the other ALUCOBOND® panels. However, only Standard and Without flanges are available as possible connection types here.

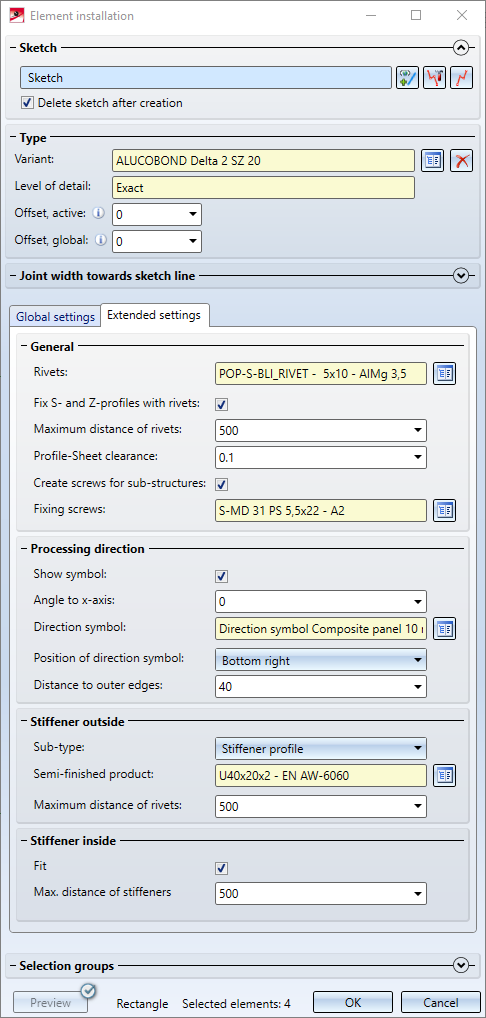

Extended settings

On this tab you define the processings for the suspension and stiffener profiles.

- Under General you select the rivets and screws for fastening the profiles to the sheet.

If the S and Z profiles (suspension profiles) are to be riveted to the sheet, then activate the corresponding checkbox and determine the maximum spacing of the rivets.

By activating the corresponding checkbox, you can determine whether the screws are to be generated for the substructure.

If the mitre cut is to be displayed in the sheet unwinding with milled edge, then activate the corresponding checkbox.

- By activating the Processing direction checkbox and specifying an angle, you can define the grain direction of the sheets. In addition, you can select the direction symbol and define the position of the symbol as well as the distance to the outer edges of the sheet..

- Under Stiffener outside / Stiffener inside, define which stiffening profiles are to be installed. Note that stiffener profiles inside are only possible if the checkbox Fix S- and Z-profiles with rivets is inactive. Select the rivets in each case and determine the maximum spacing of the rivets or the stiffeners. The stiffening profiles within are evenly distributed based on the maximum spacing.

Stiffener profiles are always riveted to the sheet.

Instead of the stiffening profiles at the edge, the material can also be double edged. For this purpose, the option Double folding is available in the selection box Sub-type.