Information > 3-D, Further > Design Checker

The Design Checker is a tool that enables you to increase the quality of your drawings and reduce costs and time through an early detection of errors in the design. You can auto-check your drawings for their compliance with specific construction guidelines; it detects, for example, invalid features, incorrect bolting sets, dummy parts, and much more. If any errors are detected, HiCAD issues an appropriate message and suggests corrections.

A number of tests that cannot be modified has been predefined by the ISD. However, administrators or users with programming skills can define their own tests and use them in the Design Checker. The testsare based on the HiCAD .NET API and can be formulated in the programming languages C# or Python. This is the same method that is used for the definition of rules and constraints for Design Variants.

When you call the function, the Design Checker dialogue window will be displayed:

HiCAD checks the active drawing or all assemblies of the selection list. Activate the desired option in the Test execution area. As long as the dialogue window is open, you can freely change the selection list to be checked.

|

Start |

Use this button to start the check. All checks specified in the Available checks field. |

|

Stop |

This symbol replaces the start symbol while the check is being performed. If you click on the symbol, the check will be cancelled. |

|

Close |

Use this button to close the dialogue window. |

Select the checks that you want to perform and click the Start button to execute the checks. The current state of the check is indicated by the Test and Total progress bars in the dialogue, separately for the currently performed check and the total progress for all checks.

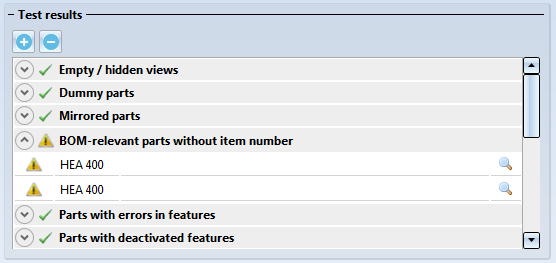

The results of the checks will be shown in the Test results pane.

The symbols have the following meaning:

|

|

No errors or warnings have been detected. |

|

|

Errors or warnings have been detected. |

|

|

The check could not be performed (e.g. if the script belonging to the check was faulty, or if the drawing contains assemblies to which the check could not be applied). |

Click the  symbol to obtain more detailed information on the test results. To expand or collapse all test results, click

symbol to obtain more detailed information on the test results. To expand or collapse all test results, click  or

or  , respectively.

, respectively.

The symbols within a test result have the following meaning:

|

An error has been detected / warning. |

|

No errors have been detected. |

When you click on a result list item, the corresponding part will be highlighted in your drawing. A multiple selection of parts (press CTRL+click) is also possible. The highlighting will still be preserved if you move or rotate the view while the Design Checker is open.

Click the  symbol to zoom in on the part causing the error.

symbol to zoom in on the part causing the error.

Important:

Important:

In addition to the checks that were predefined by the ISD, you can also define your own checks and use them in the Design Checker. These checks need to be based on the HiCAD .NET API and must be provided as Python scripts. User-specific checks should only be defined by administrators or users with sound knowledge of the HiCAD API and Python script creation. The availability of checks in the Design Checker as well as the configuration of the tree structure of the checks can be specified in the DesignChecks.XML file in the HiCAD folder Script.

The following checks have been predefined by the ISD:

General checks

Feature checks

Steel Eng. checks

Further tests

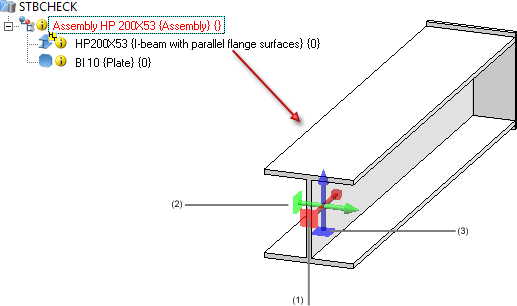

For this test the following requirements must be met:

For this test the following requirements must be met:

(1) X-direction: Length, (2) Y-direction: Width, (3) Z-direction: Height

After applying any changes in the Configuration Editor, restart HiCAD to ensure that the changes will take effect.

After applying any changes in the Configuration Editor, restart HiCAD to ensure that the changes will take effect.

Sheet Metal

Glass

Please note:

Please note:

pull-down menu.

pull-down menu. Related Topics

Information - Other Functions • Information - Data Structure Check

|

Version 2102 - HiCAD Basics | Date: 15/11/2016 | © Copyright 1994-2016, ISD Software und Systeme GmbH |