DSTV NC Interface

Drawing > Save/Print > Save as  > Further... > DSTV-NC

> Further... > DSTV-NC

This function enables you to prepare HiCAD files for export to NC equipment. The type of machine targeted determines whether the DSTV-NC or NCX Interface will be selected.

The NC Interface creates for each itemised part a NC file with the file name extension .NC. This file contains information such as attributes of the part, processings (maximum bore diameter, arcs etc.). The designation drawing_Pn is used as file name, with drawing being the name of the current drawing and n the item number of the corresponding part.

When you itemise the drawing, the Powder marking lines and punch marks acc. to DSTV-NC export checkbox shold be active, to ensure that the corresponding data will be considered for DSTV-NC export.

When you itemise the drawing, the Powder marking lines and punch marks acc. to DSTV-NC export checkbox shold be active, to ensure that the corresponding data will be considered for DSTV-NC export.

Please remember that only itemised parts can be exported.

Please remember that only itemised parts can be exported.

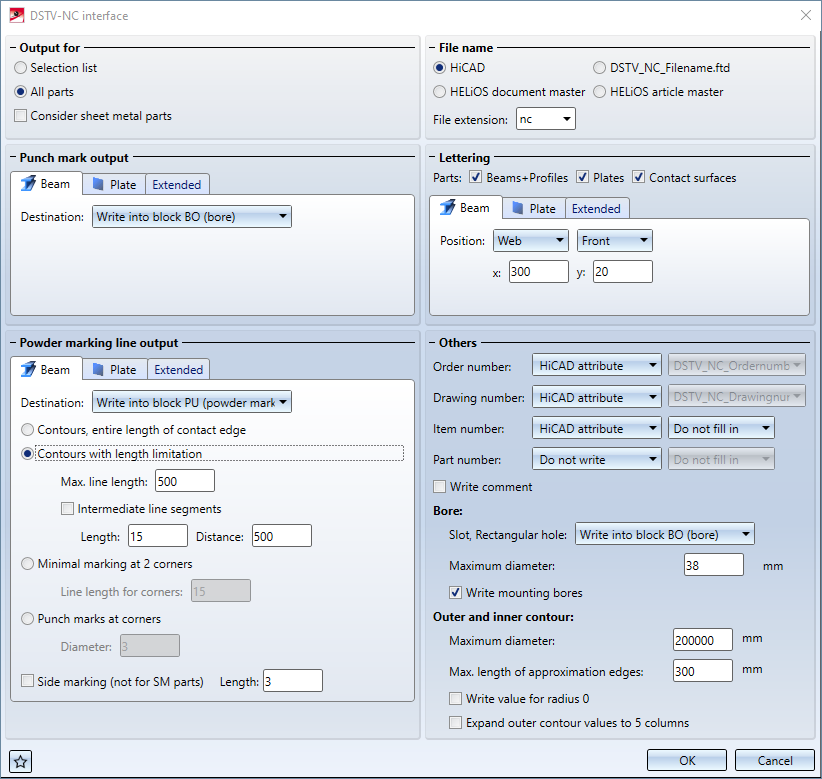

The dialogue window consists of the following areas:

Please also read the information given in the paragraphs Templates for attribute assignment and the notes at the bottom of this page.

![]() Please note:

Please note:

The settings for DSTV export can be saved as Favourites and re-used at any time. To do this, click the  icon at the bottom left of the window. The Favourites for DSTV-NC export will be saved as XML files to the directory Configuration\Favourites\SteelEngineering\DSTV-NC of your HiCAD installation.

icon at the bottom left of the window. The Favourites for DSTV-NC export will be saved as XML files to the directory Configuration\Favourites\SteelEngineering\DSTV-NC of your HiCAD installation.

Favourites are saved to the same-named sub-folder of the directory in which the HiCAD Configuration database is also located. If you have installed HiCAD from the red DVD with the ISD default settings, this will be the folder ProgramData\ISD Software und Systeme\HiCAD nnnn, with nnnn being the HiCAD version, e.g. 2017.

More on Favourites Management can be found in the Manage Favourites topic of HiCAD Basics Help.

Output for / File name

At the top left of the window, under Output for, you can select whether All parts should be exported or only a Selection list, i.e. the active part list.

Furthermore, by activating / deactivating the Consider sheet metal parts checkbox, you can determine whether sheet metal parts should be exported or not.

At the top right of the window, under File name, you can select how the export file is to be named:

- according to the HiCAD file name,

- according to the HELiOS document or article master (if you work with database) or

- according to the template file DSTV_NC_Filename.ftd.

Punch mark output

For the Punch mark output you can, if punch marks exist, specify separately for beams and plates whether these should be written and, if so, where:

- Write into block BO (Bore)

- Write info block KO (Punch mark)

- Do not write

If you activate the Calculate punch marks automatically checkbox on the Extended tab, non-existing punch marks are automatically determined and written to the DSTV NC file. Existing punch marks will not be replaced or changed.

If the Display punch marks as points checkbox is also active, these automatically determined points are not only exported to the file, but are also displayed visually in the HiCAD drawing. These are then isolated points, not actual machining operations. If necessary, you can define the exact Edge distance of these points yourself in the input field.

In the Configuration Editor (ISDConfigEditor.exe), the displacement dimension for punch marks can be preset at Steel Engineering > DSTV-NC.

Powder marking line output

You proceed in a similar way for Powder marking line output:

- Write into block PU (Powder marking line)

- Write into block KO (punch mark)

- Do not write

In the Beam and Plate tab you can specify various settings, such as the general Length of the Side marking, or extended settings concerning contours and identifications.

Besides the representation option Contours, entire length of contact edge option, you can choose between the following three other options:

Contours with length limitation: For the representation of the mounting of longer parts, the powder marking line can be replaced with a intermediate segmented line whose segment lengths and the distances between them can be specified. Default values are a length of 15 mm and a distance of 500 mm.

Minimal markings at 2 corners:

Marks two corners and the connecting side of the attachment part. Specify a value for the Line length for corners.

Punch marks at corners

For symmetrical parts that are rotated 90 or 180 degrees about the beam axis, there will be several possible attachment positions. This requires a clear and unambiguous marking of the connection side by means of punch marks. Specify a Diameter.

1: Contour representation, entire length; 2 Contour representation, limited length

In the Extended tab, you can also define the Distance tolerance, Angle tolerance and Min. length under Tolerance for powder marking line search.

Under Powder marking line output, you can define that manually assigned powder marking lines are to be output by activating the Manually created option. In this case, the input fields for marking in the Beam and Plate tabs are greyed out. If, on the other hand, the Automatic option is active, then the powder marking lines are created automatically and manually created powder marking lines are not taken into account.

Lettering

In this area you can determine whether letterings for beams, plates and contact surface should be created automatically.

- Beam

The position of the lettering of beams can be defined either at the front or at the back of the flange or web with specification of the X- and Y-coordinates (input fields). - Plate

The position of the lettering of plates can be defined at the front or at the back with specification of the X- and Y-coordinates (input fields).

- Extended

Here you specify the text of the itemization. The following options are available:- Item number

- Drawing number/Item number

- 4-digit drawing number/Item number

- Order number/Item number

- From template file

Here the text is determined by the template file DSTV_NC_Signaturetext .FTD. This file can be customized using the Templates for attribute assignment function.

In the Configuration Editor (ISDConfigEditor.exe), you can set at Steel Engineering > DSTV-NC whether the item number of the higher-level assembly is to be output for main parts.

Others

Here you determine whether the Order number, Drawing number, Item number and Part number should be output and, if so, how. The following options are available:

- Do not write

No value is written out for the attribute. - HiCAD attribute

The corresponding HiCAD drawing attribute is used ("Order number" / "Drawing number" or "Drawing name" / "Item number"). - From template file

The text is formed according to a DSTV-NC template file. To do this, select the desired template file. All FTD files in the HiCAD sys directory whose name starts with DST_NC_ are available for selection. These can also be your own templates that you have saved using the 3-D Dimensioning+Text > Text > LLine > Change font function.

> Change font function.

In the case HiCAD attribute was selected, you can specify how many digits the number should be padded to next to Item number and Part number.

Write comment

Activate this checkbox if comment lines are to be output.

Bore

Here you can define for slots and rectangular holes in which block - BO (Bore) or IK (Inner contour) - the data should be written. In addition, you can define a maximum diameter for the bore output.

By deactivating the checkbox Write mounting bores you can exclude bores from the export.

Outer/inner contour

Enter the maximum values for the arcs of the outer and inner contour and select the block for the output - BO (Bore) or IK (Inner contour). If you also want to output a value for the third coordinate or the radius, even if it is 0, activate the checkbox Write value for radius 0.

After selecting the desired options, click OK and specify the directory for the export data in the following dialog. Here you can also freely select a file extension.

Templates for attribute assignment

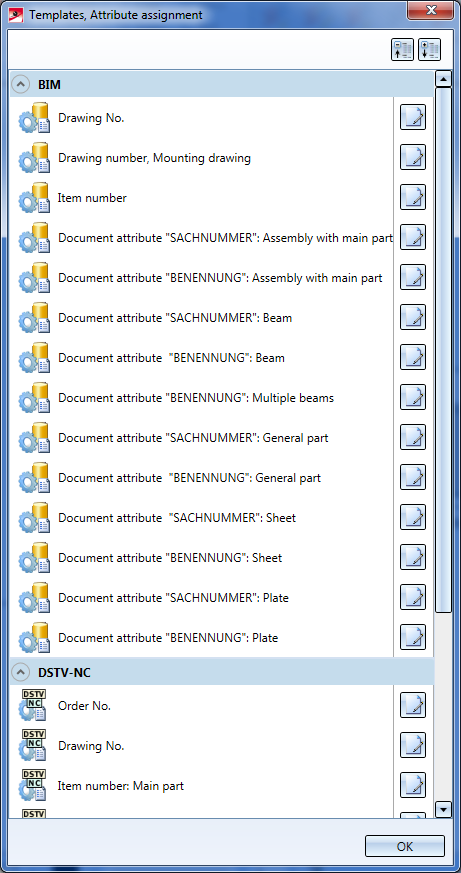

Open the Drawing tab and choose Itemisation/Detailing > Attr.  > Templates, Attribute assignment

> Templates, Attribute assignment  to open the Templates, Attribute assignment dialogue window.

to open the Templates, Attribute assignment dialogue window.

Scroll down to the DSTV-NC section.

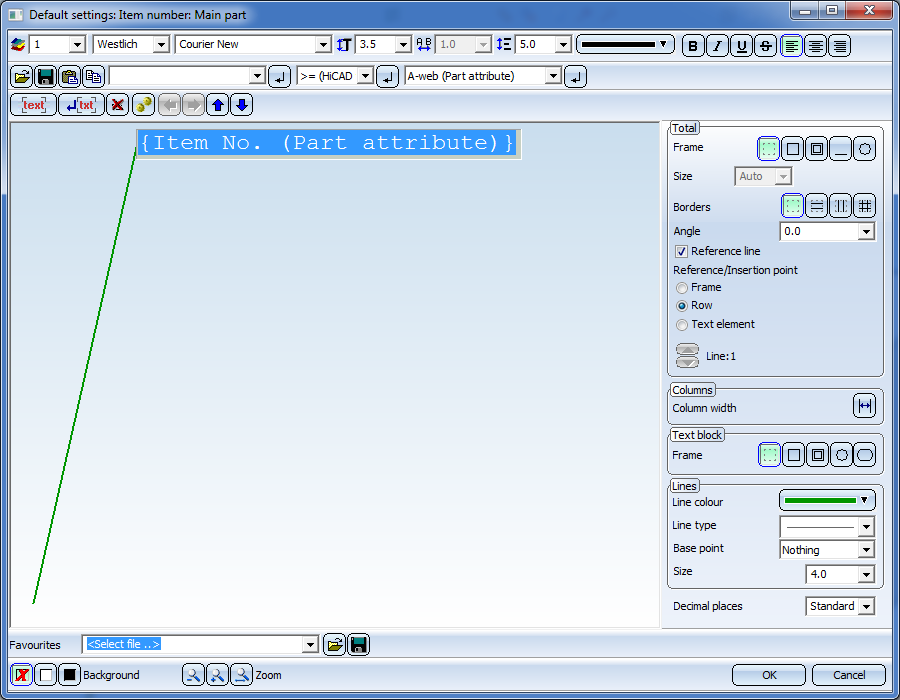

Clicking one of the editing symbols opens the Editor for for the annotation settings - here, the Item number: Main part entry has been chosen:

The templates for attribute assignment for DSTV-NC export are FTD files, too; they are located in the sys directory of your HiCAD installation. Supplied with HiCAD are the templates listed below:

|

Templates file |

Settings for |

Pre-setting |

|

DSTV_NC_Ordernumbertext.ftd |

Order number |

%TS(TEXTE760) %TS(TEXTE760) stands for the content of the text key TEXTE760, which is the text Order number: |

|

DSTV_NC_Drawingnumbertext .FTd |

Drawing number |

%TS(TEXTE1AN113) %TS(TEXTE1AN113) stands for the content of the text key TEXTE1AN113 which is the text Drawing number: |

|

DSTV_NC_H_Itemnumbertext .FTd |

Item number for main parts |

{Item number (Part attribute)} |

|

DSTV_NC_H_Partnumbertext .FTd |

Part number for main parts |

not allocated |

|

DSTV_NC_Itemnumbertext.FTd |

Item number for loose parts |

{Item number (Part attribute)} |

|

DSTV_NC_Partnumbertext.FTd |

Part number for loose parts |

not allocated |

|

DSTV_NC_W_Itemnumbertext.FTd |

Item number for attached parts |

{Item number (Part attribute)} |

|

DSTV_NC_W_Partnumbertext.FTd |

Part number for attached parts |

not allocated |

|

DSTV_NC_Signaturetext.FTd |

Signature |

{Item number (Part attribute)} |

|

DSTV_NC_Filename.FTd |

File name - NC |

{Item number (Part attribute)} |

- Processings on beams and profiles with circular (i.e. "infinite") cross-sections will not be written out. Only the header data will be written for this beam/profile type.

- After completion of the export, a protocol file (conversion log) containing errors and information about the data transfer will be displayed. Double-click a log entry to show further information. The data are saved in a LOG file.

- The DSTV-NC and NCX interfaces generate log files with the file name extension .LOG during export.

- In the Configuration Editor at Active configuration (Base configuration) > Steel Engineering > DTSV-NC you can specify for the DSTV-NC interface:

- which attribute is to be used as item number for "H" parts. If the Use item number of assembly checkbox has been activated, the assembly item number will be used.

- Displacement of punch marks: The inward displacement of punch marks located on edges can be entered here as a decimal number. The default value is 0.

- The setting for maximum bore diameter is only considered for through holes; countersinks of whatever diameter will always be written into the "BO" block.

DTSV Product Interface • DSTV BOM Interface • Steel Engineering Interfaces