Information > 3-D, Further > Radial pin calculation

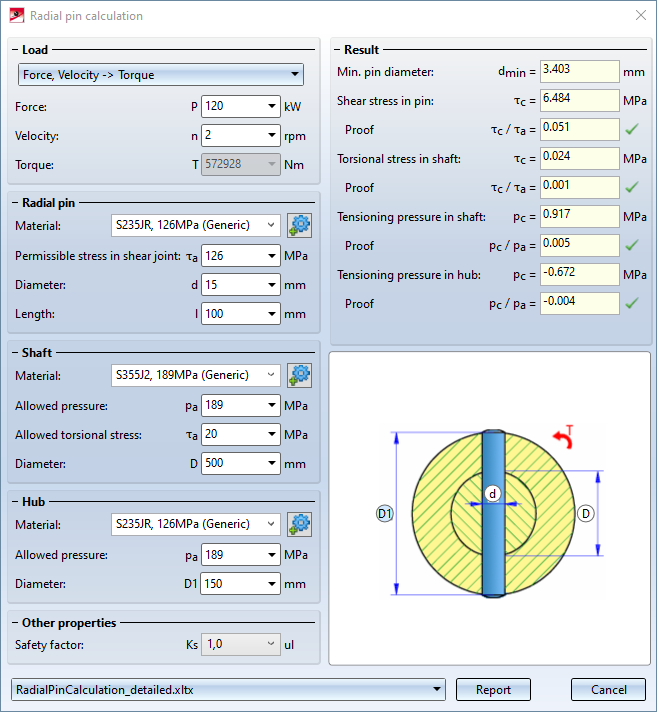

Use this function to check whether a radial pin that was inserted for the connection of a shaft and a hub has the required stability. The function calculates the minimum diameter of the pin, the shear stress in the pin, the torsional stress and the tensioning pressure in the shaft, and the tensioning pressure in the hub.

When you call the function, the Radial pin calculation will be displayed.

The dialogue window consists of the following areas:

|

Load |

Force, Velocity and Torque must be specified here for calculation. One of these values will always be calculated from the other two values. This means that there are three possibilities:

Choose the desired procedure from the selection box and enter the corresponding values. |

|

Radial pin |

By selecting the Material the permissible stress in the shear joint will be automatically determined. Material, pin diameter and pin length (effective length without chamfers and fillets) can also be directly taken from the drawing. To do this, click the The value for the pin diameter and the pin length can also be taken from the drawing as follows: Right-click in the input field and select Pick distance from the context menu. |

|

Shaft |

Material and Diameter can also be directly taken from the drawing. To do this, click the The value for the diameter can also be taken from the drawing as follows: Right-click in the input field and select Pick distance from the context menu. |

|

Hub |

Material and Diameter can also be directly taken from the drawing. To do this, click the The value for the diameter can also be taken from the drawing as follows: Right-click in the input field and select Pick distance from the context menu. |

|

Safety factor |

This factor stands for the type of load:

|

The following values are calculated automatically:

- the minimum diameter of the pin,

- the shear stress in the shear joint,

- the torsional stress in the shaft,

- the tensioning pressure in the shaft,

- the tensioning pressure in the hub.

Passed stress tests will be marked with the  symbol, failed tests are marked with the

symbol, failed tests are marked with the  symbol.

symbol.

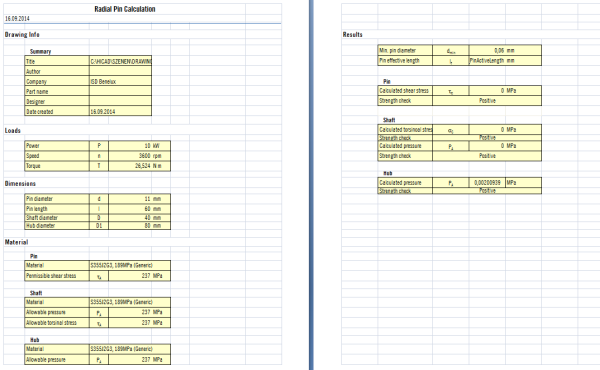

Click the Report to display the result of the test in an Excel file. The following templates are available for this purpose:

- RadialPinCalculation_detailed.xltx (English) and

- RadialStiftBerechnung_detailliert.xltx (German)

Please note:

Please note:

You have also the option to use your own templates. These can be created by copying and customizing of the templates that were defined by the ISD and supplied with HiCAD.The templates must be saved to the HiCAD directory templates\SecurePinCalculation. To achieve that these templates will actually be offered for selection in the dialogue window for the radial pin calculation, open the Configuration Editor, select ... > System settings > Calculations > Radial pin calculation, and expand the list accordingly.

symbol and identify the radial pin in the drawing.

symbol and identify the radial pin in the drawing.