Create WinIso 2-D part

Use this function to specify the area for the WinIso calculation by drawing a selection rectangle in a sectional view.

Please note that the existence of a sectional view is mandatory for this function.

Transparent area

Use this function to define a transparent area for windows and glass panes (for further details please see the WinIso Help). To do this, first select an edge running parallel to the transparent area. Then, specify the start and end point. The transparent areas are indicated by means of edges in the WinIso 2-D part.

The execution of this function is optional.

Distance for Ug value

Use this function to define the distance determining the heat transfer coefficient (Ug value) of a glazing (for further details please see the WinIso Help).

To define a distance for the Ug value, first select an edge running parallel to the glass pane. Then, specify the start and end point on the inner and the outer glass side. The distances for Ug value definition are indicated by means of edges in the WinIso2D figure.

The execution of this function is optional.

Export

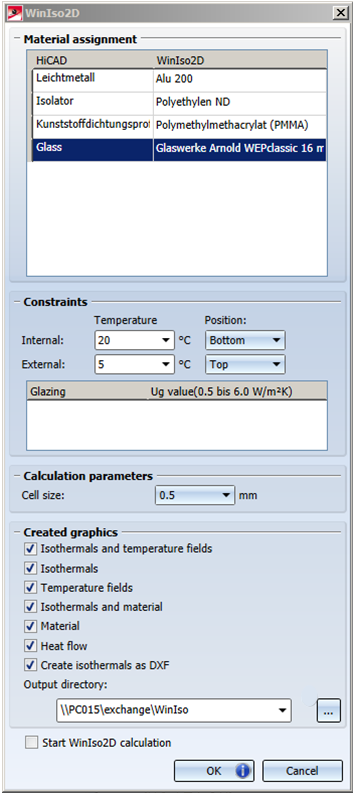

This function starts the export of the WinIso 2-D part. When you call the function, the following dialogue window will be displayed:

- Material assignment

Here you assign the WinIso material designations to the HiCAD material designations (mapping). - Constraints

Here you can specify the temperature and the position (separately for inside and outside). The mid-points of the selected edges (top, bottom, left, right) of the environment rectangle will be transferred to WinIso2D as reference points. -

Calculation parameters

Cell size for the WinIso calculation. -

Created graphics

Determines which output files are to be created by WinIso. The names of the output files have been predefined by WinIso (for further details please see the WinIso Help). - Output directory

Here you specify the storage location of the output files. -

Start WinIso2D calculation

If this checkbox has been activated, the WinIso calculation will start immediately after confirming with OK. HiCAD will then use the command line for the calling of the WinIso2D calculation (see "Please note" section at the bottom of page).

Please keep to the procedure described below.

to create a new sectional view. In the dialogue window, activate the

to create a new sectional view. In the dialogue window, activate the