JACOB Pipe Systems - Flange Dimensions of Pull-Ring Connections

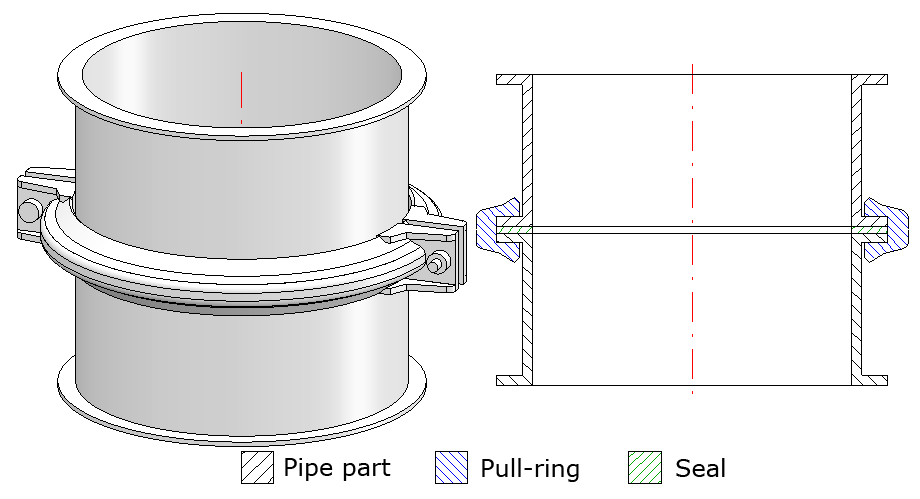

The flanged edges of the parts play an essential role for the pull-ring connections. Pull-rings are mounted by placing them over one flanged edge of each of the parts to be connected, and fixing them by tightening of the screws or a clamping lever. In practice, the locking of the parts will be realised by means of a (partly) elastic adjustment of pull-ring and seal.

In parametric designing, the seals and pull-rings have been simplified to a sub-type-specific, rigid geometry for the sake of an easier handling.Depending on wall thickness and nominal diameter of the parts to be connected, consistent dimensions are therefore required for the flanged edges, to ensure a collision-free, yet tightly locked insertion of seals and pull-rings.

Composition of pull-ring connection in HiCAD

The dimensions shown in the table below have been consistently used for the construction of the supplied JACOB variants. These should also be used when you create your own sub-types, in order to ensure permanent compatibility with the pull-rings.

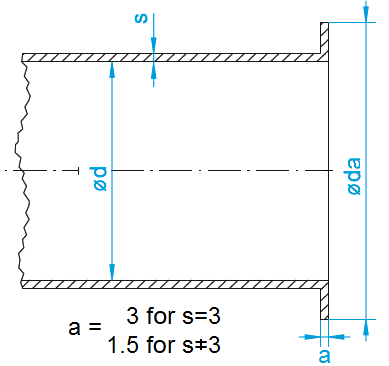

The thickness of the flanged edges was restricted to 2 constant dimensions "a" by various pull-rings for 1-2 mm and 3 mm pipes.

The thickness of the flanged edges was restricted to 2 constant dimensions "a" by various pull-rings for 1-2 mm and 3 mm pipes.

Dimension variables of the flanged connections

|

DN |

⌀ da |

⌀ d (s = 1) |

⌀ d (s = 1,5) |

⌀ d (s = 2) |

⌀ d (s = 3) |

|---|---|---|---|---|---|

|

60 |

72 |

--- |

57 |

--- |

--- |

|

80 |

92 |

78 |

77 |

76 |

--- |

|

100 |

114 |

100 |

100 |

99 |

--- |

|

120 |

135 |

120 |

120 |

119 |

118 |

|

140 |

150 |

136 |

136 |

135 |

--- |

|

150 |

165 |

150 |

150 |

149 |

148 |

|

175 |

190 |

175 |

174 |

174 |

173 |

|

200 |

215 |

200 |

200 |

199 |

198 |

|

224 |

234 |

220 |

220 |

219 |

218 |

|

250 |

265 |

250 |

250 |

249 |

248 |

|

280 |

292 |

278 |

277 |

276 |

--- |

|

300 |

315 |

300 |

300 |

299 |

298 |

|

315 |

327 |

313 |

312 |

311 |

--- |

|

350 |

365 |

350 |

350 |

349 |

348 |

|

400 |

414 |

400 |

399 |

398 |

396 |

|

450 |

464 |

450 |

449 |

448 |

446 |

|

500 |

514 |

500 |

499 |

498 |

496 |

|

560 |

574 |

--- |

--- |

558 |

556 |

|

630 |

644 |

--- |

--- |

628 |

626 |

Dimensions in mm

JACOB Rohrsysteme - Using the Variants (PE) • Plant Engineering Functions