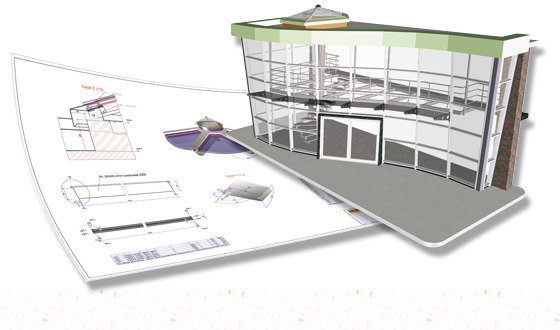

Why 3-D?

Today more and more companies are using 3-D model drawings to reduce their product development times and thus to withstand international competitive pressure. The advantages of 3-D models, however, are often still underestimated although they contribute significantly to a higher competitiveness and can be used effectively in many departments of an enterprise.

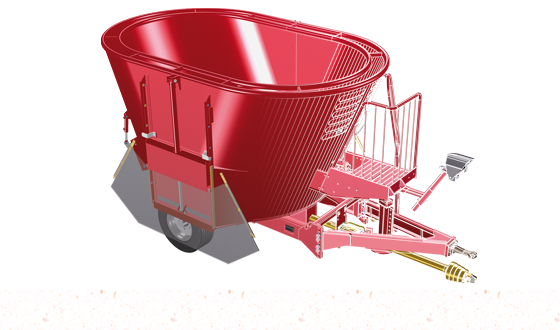

- Realistic visualisation

3-D CAD systems enable a realistic visualisation of parts and assemblies. The 3-D model can be displayed in a photo-realistic manner by means of illumination or assigning of material properties, and can thus be presented in a promotionally much more effective way than a 2-D drawing.

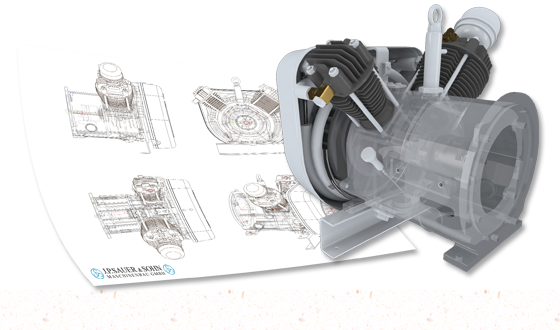

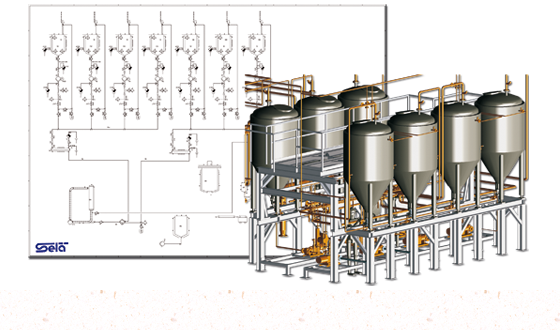

- Error reduction

3-D model drawings can be used for the evaluation of prototypes directly during the design phase and the reviewing of their functionality at early stages. The earlier errors are recognized, the easier it is to correct them. This improves product quality and also contributes to cost reduction. For example, exploded views can be automatically derived from the 3-D model, while transport, motion or assembling processes can already be checked during the design process, thus enabling an early detection and elimination of errors.

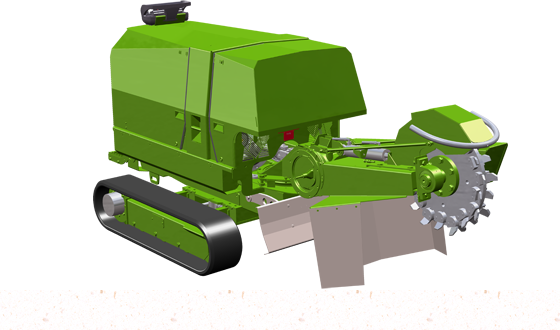

- Flexible designing

Working with 3-D model drawings is much easier and more efficient: For example, if you drill a bore in a 2-D object, you will also have to adjust the different views of the corresponding 3-D model one by one. In 3-D, you drill the bore in your 3-D model, and the relevant production drawings are automatically adjusted accordingly. Furthermore, the use of a wide range of technologies, e.g. the feature and design variant technology, enables you to significantly streamline repetitive routine tasks.

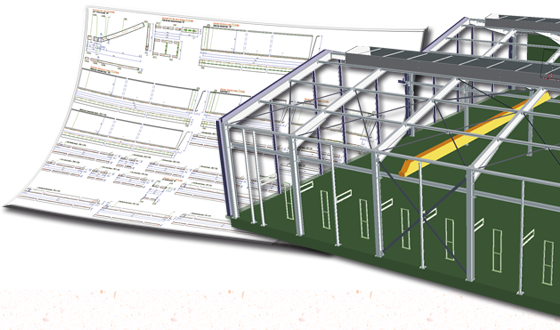

- Faster product development

A 3-D model drawing contains much more information than a simple 2-D drawing. This enables you to use downstream applications to process 3-D models, make analyses and simulations of the virtual model as well as FEM calculations or the automatic generation of tool paths.