In this example, we will use the model shown below:

The three boxes (2), (3) and (4) are to be moved along the conveyor and pushed into the container on the floor (6) by the pushing device (5).

This type of simulation is realised in the Physical simulation mode, with the help of

In addition, the following HCM constraints must also be defined for the assembly, to prevent an uncontrolled moving of the parts:

|

(1) Coincidence |

(2) Coincidence |

(3) Coincidence |

(4) Coincidence |

|

(5) Coincidence |

(6) Coincidence |

(7) Coincidence |

(8) Fixing |

To perform the simulation, proceed as follows:

Step 1: Create the simulation:

.

.  and select Deactivate

and select Deactivate  .

.

Step 2: Define the motors for the pushing device.

The pushing device must be able to move forwards and backwards to push the boxes into the container on the floor. This means that two translation motors will be needed - one for the forward movement, and one for the backward movement.

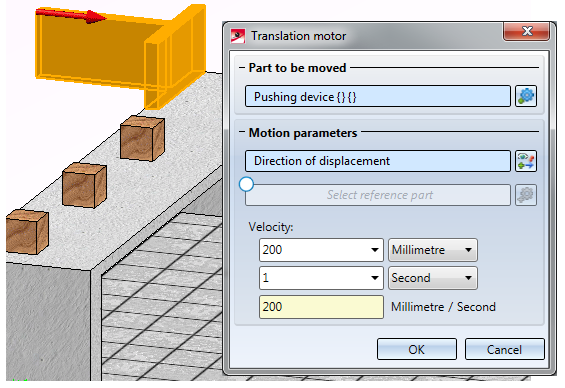

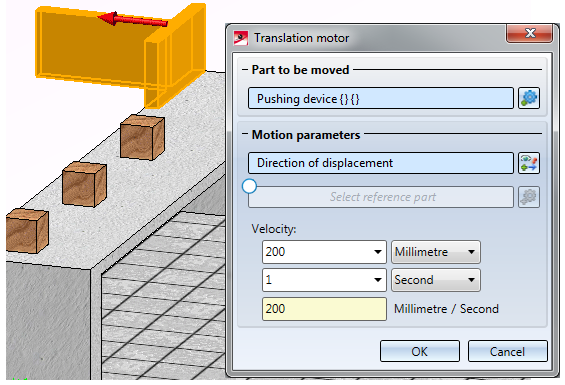

(for the forward movement)

(for the forward movement)

The part to be moved is the pushing device: Click the  symbol and identify the pushing device in the ICN or in the drawing.

symbol and identify the pushing device in the ICN or in the drawing.

Define the direction of the displacement by clicking the  symbol and selecting the edge of the part as shown above.

symbol and selecting the edge of the part as shown above.

Velocity: 200 mm/s

again, and proceed as described above for the definition of the backward movement.

again, and proceed as described above for the definition of the backward movement.

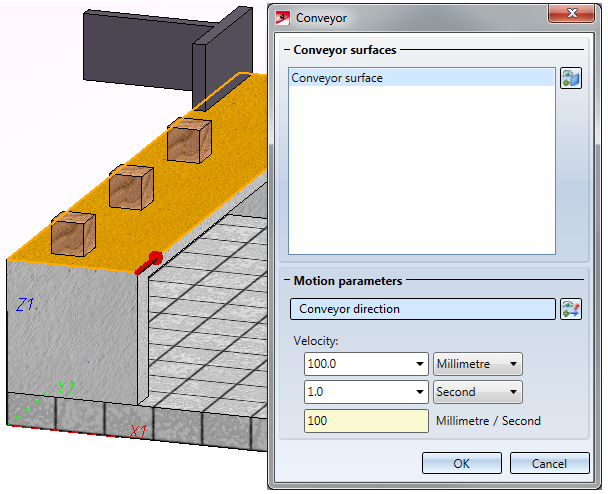

Step 3: Now define the conveyor.

.

.

Make the top surface of the part "Conveyor" the conveyor surface: Click the  icon and identify the top surface.

icon and identify the top surface.

Define the conveyor direction by clicking the  icon and selecting the edge of the part as shown above.

icon and selecting the edge of the part as shown above.

Velocity: 100 mm/s

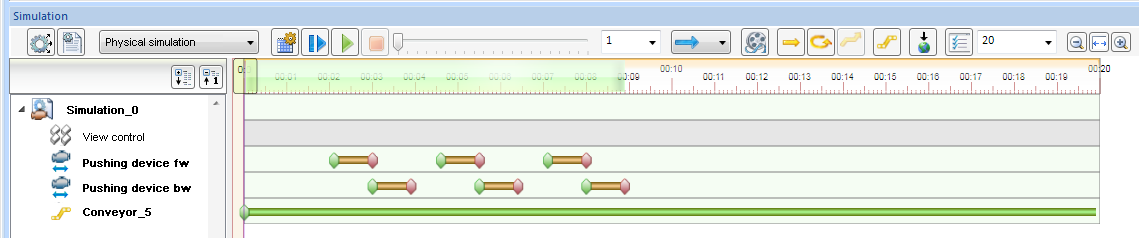

Step 4: Specify the time intervals.

Now specify the time intervals for motors and the conveyor. The conveyor must move uninterruptedly.

The motors for the pushing device must be moved in intervals, because the pushing device may only be moved forward again after the next box had been transported to the required position. As three boxes are to be moved, 3 time intervals for each motor will be required.

Step 5: Calculate  the simulation.

the simulation.

Video of the simulation

Simulations (3-D) • The 'Simulation' Docking Window (3-D) • Simulation: Examples (3-D)

|

© Copyright 1994-2018, ISD Software und Systeme GmbH |